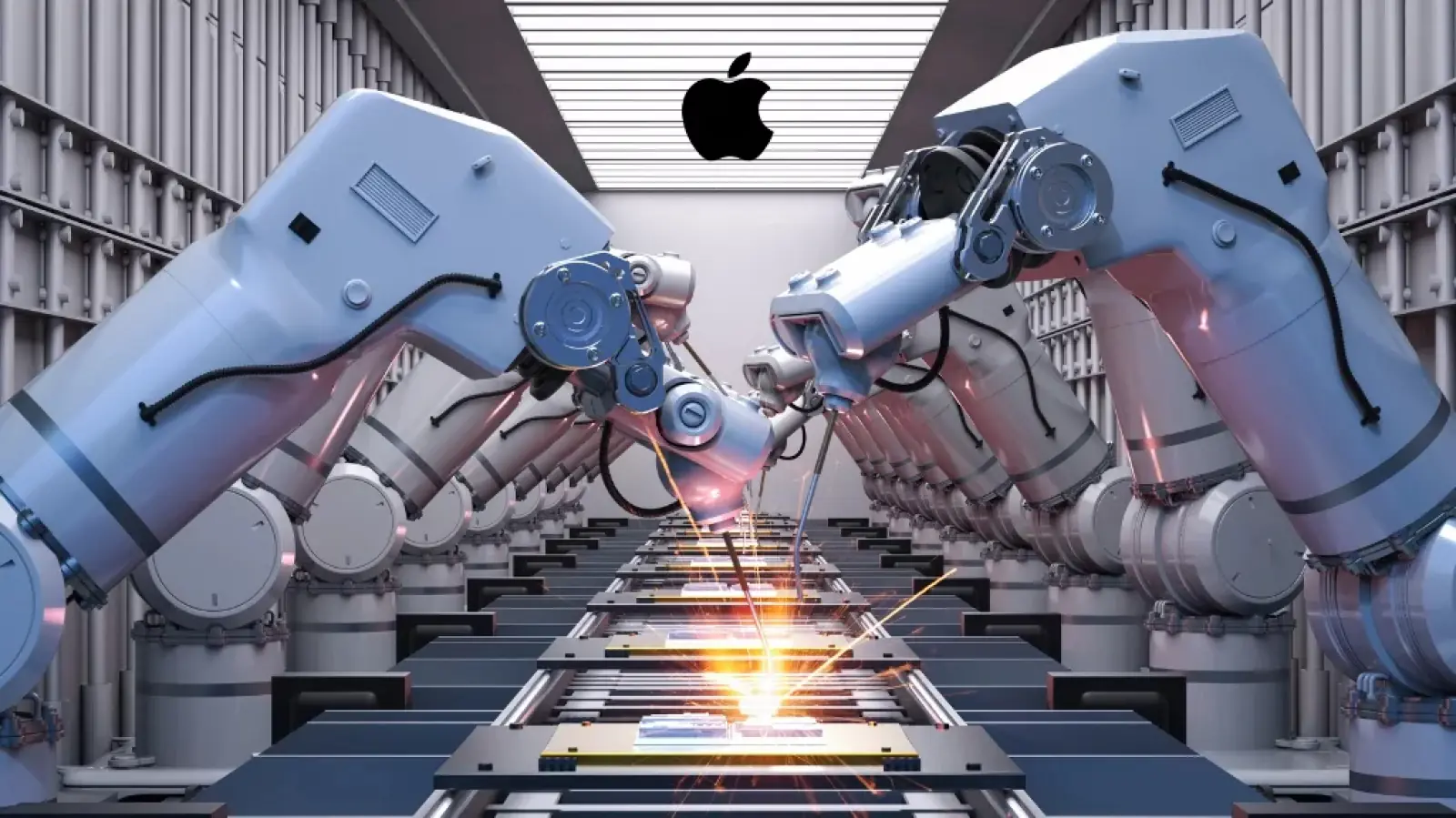

Robots will now make iPhones in the world's largest factory, eliminating the need for humans

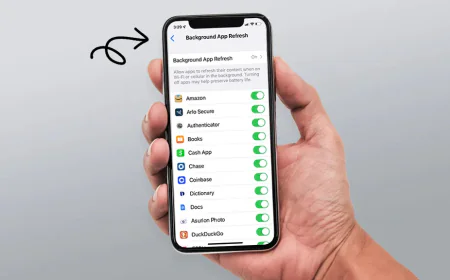

Robots: Young Liu said that Foxconn has already incorporated generative AI into its workflow, which has accelerated production efficiency. AI-supported software is able to automate 80% of the work of setting up a new production line, saving both time and cost.

The global leader in contract electronics manufacturing and top supplier of iPhone to Apple will be embracing full automation in the very near future. The chairman of the company, Young Liu, has indicated at Computex 2025 in Taipei that in the future, factories will be operated by robots and generative AI, almost eliminating low-skilled human labor.

Young Liu explained that Foxconn has already integrated generative AI in its operations and, thus far, has seen production efficiency improve as a result. It can automatically perform 80% of the task of opening a new line of production through AI-powered software and save both time and money.

"We thought maybe we could replace every human, but soon realized that it was not possible," he said. AI is now helping the company solve production problems quickly, and human experts can now focus on more valuable tasks.

Want to get your story featured as above? click here!

Want to get your story featured as above? click here!

Foxconn is now also building its own AI model called FoxBrain, which will combine Meta's Llama 3 and 4 models with the company's operational data to create an agentic workflow. The model will help solve ground-level tasks in the factory, and the company plans to open-source it.

Foxconn builds about 10,000 Foxbots every year, which are replacing human workers. The company already claims to have automated 60,000 jobs at one factory and aims to automate 30% of its Chinese plants by 2020.

Foxconn is now also building and simulating digital twin factories using Nvidia's Omniverse, allowing a factory to be planned and processes optimized with AI before it's even built.